Our technology offerings are supplied through a battery of tests, including flocculant screening, static and dynamic thickening and diligent rheological analysis. These bench-scale tests can be scaled into pilot-scale thickener testwork and/or flume model testing to assist with thickened/paste deposition on slopes up to 6%.

Competitive Advantage

Fast delivery time

Our modular approach to thickener design and fabrication allows for swift assembly of drawing packages, enabling SMPP manufacturing to commence promptly. This efficient process results in industry-leading turnaround times for delivery and minimizes logistics costs to site.

Outstanding performance

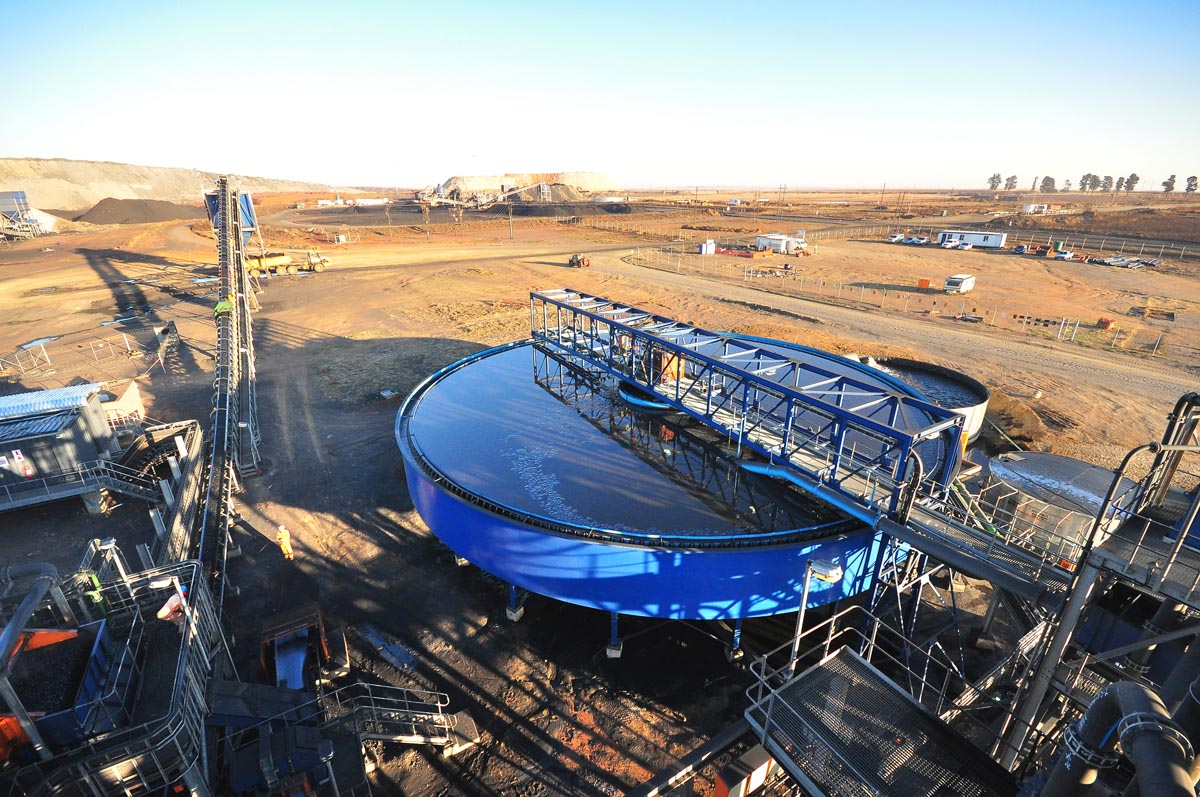

Our thickeners excel in continuous process applications for solid-liquid separation via sedimentation, demonstrating exceptional performance across various industries. With manufacturing capabilities on four continents, we minimize shipping and delivery times for your project.

International experience

Our team has extensive experience in deploying installations in challenging jurisdictions. Thanks to our multilingual and multi-disciplinary teams, project expediting and construction schedules are effectively managed to ensure timely completion.

Quality standards and low capital cost

While our engineering and design adhere to North American standards, including Canadian engineering and QA-QC standards, we utilize overseas manufacturers to remain competitive. Our equipment design balances conservatism and robustness, ensuring longevity and sustained operation.

Varying thickener sizes

We can supply a variety of high density, high compression, and paste thickener sizes, from 1-metre pilot-scale units to 90-metre diameter, including standard designs and custom options based on feed conditions. We also offer retrofit services to improve existing thickeners' performance.

Bolted design advantage

We offer bolted designs for expedited fabrication, shipping, and installation, minimizing on-site welding and simplifying transportation. These designs are flexible for relocation or repurposing and feature a low-friction rake lift mechanism for improved operational efficiency.

Technology Highlights

Our Process

Our projects evolve, enhancing our understanding, engineering precision, and cost accuracy. We guide clients through this journey, ensuring timely achievement of investment targets. Unlike traditional OEMs, we provide a dedicated contact for comprehensive support from start to finish.

Project Benchmarking

Project Benchmarking

Utilizing a decade's worth of data from labs and operations, coupled with observational analysis, we've created an AI model. It rapidly evaluates material "filterability" by examining their physical, chemical, and mineralogical traits. This assists in predicting costs for different filtration methods, aiding early decision-making and validating engineering feasibility.

Bench-Scale Testwork

Bench-Scale Testwork

To optimize testwork accuracy and quality control, we've launched our subsidiary, Canadian Critical Minerals Research, conducting all bench-scale tests for clients. Our process involves collaboration between technicians and engineering staff to integrate learning outcomes into project stages. Unlike other OEMs divesting in-house labs, we're heavily investing in our 3,000 sq. ft. facility in Kamloops, BC, ensuring comprehensive services.

Conceptual Engineering and Process Flowsheet Development

Conceptual Engineering and Process Flowsheet Development

We offer conceptual engineering services alongside initial testwork results to merge data into practical outcomes. Our process integrates sample data, mineral processing principles, and a mix of proprietary and standard equipment. These studies finalize major process elements, enabling estimation discipline.

Pilot-Plant Testwork

Pilot-Plant Testwork

For complex projects, longer-term pilot-plant testwork may be necessary to validate data over time due to sample variability. Our facilities can handle large sample volumes and equipment for onsite pilot studies. We also provide containerized and mobile test rigs for global deployment to customer sites.

Front-End Engineering (FEED) and Detailed Engineering

Front-End Engineering (FEED) and Detailed Engineering

Once the process flowsheet design is confirmed, we advance the project into a FEED study to improve estimate accuracy. This includes finalizing piping and instrumentation diagrams, equipment lists, and specifications for vendor engagement and procurement. With in-house engineering expertise, we also collaborate with trusted third-party consultants as needed.

Project Execution & Construction

Project Execution & Construction

With vast experience in managing large-scale capital projects across remote areas, our team has successfully built plants in numerous countries. We handle all project execution functions, including procurement, logistics, quality assurance, and more. Our personalized project management services add significant value, with our team often acting as owner’s

Operational Readiness (OR)

Operational Readiness (OR)

Operational Readiness is crucial for seamless handover of information from engineering to operations. Our OR phase includes thorough HAZID/HAZOP analysis and collaboration with vendors, ensuring a well-prepared workforce for day-to-day operations.

Commissioning

Commissioning

Upon delivery, we inspect facilities for compliance and authorize equipment installation. We oversee construction verification and assist with assembly as per specs. The commissioning team supervises dry commissioning to detect issues. Wet commissioning follows, transitioning to live operations with slurry feed for filtration.

Operations

Operations

After reaching steady-state operations, we support clients through the post-commissioning phase, known as the "valley of death." Our commissioning team remains in operational support roles for the critical first hundred days, ensuring a smooth transition with maximum impact on return of capital.

Why Choose CEC Mining Systems?

Single Point of Contact

A single point of contact to supply full scope solutions through the project life-cycle.

Testing & Design Competency

Competency in the testing, design, and applications of traditional and novel technologies.

Strong Vendor Relationships

Effective working relationships with a diverse mix of vendors and sub-contractors to assemble the best project team.

Team Integration and Support

Integration within the end-user personnel and processes to ensure unified understanding of scope and responsibilities.

Agile Responsiveness

Highly agile responsiveness to end-user requirements.

Boutique Approach

A boutique approach to project delivery.

Startup and Commissioning

Extensive start-up and commissioning capabilities and experience in remote jurisdictions.