| HORIZONTAL

HIGH THROUGHPUT DEWATERING WITH CAPABILITY FOR SOLUBLE METAL PRECIPTATION AND RECOVERY

The CX-PSS Horizontal Belt Filter (HBF) is an efficient and reliable solid/liquid separation unit suitable for dewatering a wide range of materials. Utilizing vacuum filtration, CX-PSS HBF filters have low capital, running and maintenance costs, thereby outperforming traditional rotary drum, disc, tilting pan and table filters in all situations where capacity, efficient cake washing and minimum liquor dilution are required. Furthermore, horizontal belt filters are being well accepted to dewater process plant tailings to be used as mine backfill or sent straight to the dry stack tailings impoundment.

Unique Features

Pneumatic vacuum box lifting

Clip-on replacement vacuum strips

Optional medium wave infrared drying

Pre-assembled modular delivery

Global manufacturing capabilities

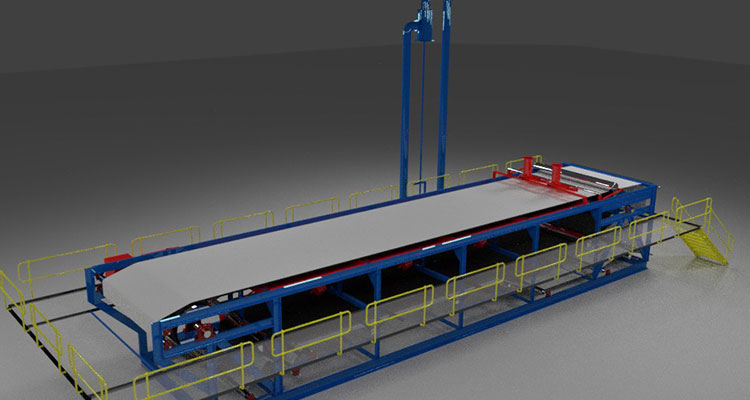

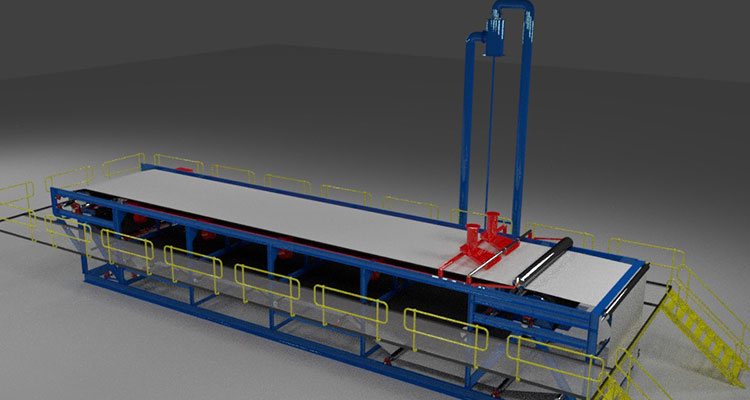

CX-PSS Horizontal Belt Filter (HBF) Design

The filter uses a screen cloth and rubber vacuum carrier belt in combination. As the fishtail feeder deposits slurry onto the surface of the filter cloth, the belt moves in a horizontal linear direction under the dam roller to form a cake of varying thickness. As the belt travels, negative vacuum pressure draws free filtrate out of the slurry, through the cloth, along the grooves in the carrier belt and through the centre of the carrier belt into the vacuum box. This process continues until the slurry has formed a solid filter-cake, which is then discharge at the head pulley end of the filter.

Main Frame – The framework is manufactured in mild steel. The sections are bolted together to provide a rigid construction with an integrated transport frame also included to allow delivery and installation of completed machines direct from the workshop. All welding work will comply with local certifications or equivalent.

Fishtail Feeder – The feed distributor is mounted over the filter and designed to distribute slurry evenly across the belt using a partitioned fishtail feeder whereby the actual partitioned “fins” can be adjusted and positioned for even slurry distribution.

Spillage launders are included along both sides of the filter to collect spillage during upset conditions. The feedboxes are rubber lined to protect against wear. Rubber lining to be 6mm thick SBR rubber.

Cake Wash – To maintain process performance, the filter cloth and transport belt passes under spray bars for cleaning by high pressure water sprays. These spray bars can also be configured to saturate the cake prior to final dewatering in order to ensure full recovery of any soluble metals in the filtrate to be recovered through precipitation later.

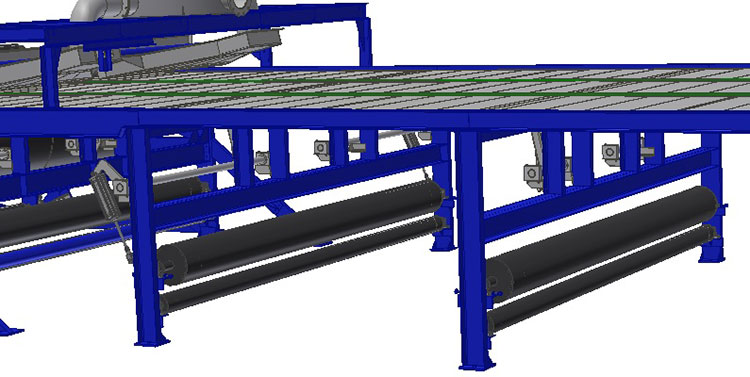

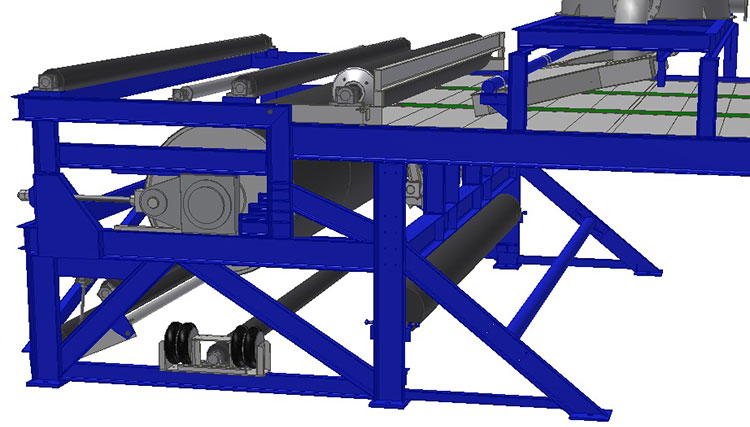

Carrier Belt – The endless rubber belt with traverse grooves drains the filtrate towards holes positioned along the centre of the belt. The side of the belt has static stainless steel skirting that contains the incoming slurry and the cake as it moves towards the discharge end.

The CX-PSS HBF belt includes a soft rubber ridge on the edge leading up to the skirting sides and guided using strong belt guide rollers. Polyamide synthetic plies (i.e. “carcasses”) are encapsulated in the rubber belt below the grooves and serve to withstand the longitudinal stresses to which the belt is subjected.

Filter Cloth – A filter cloth, the media which separates the slurry and cake from the vacuum system is made from needle felt, monofilaments, multi filaments or a combination of both (multi mono). Mono filaments are supplied in polyesters polyamides or polypropylenes.

Polypropylene cloths are hydrophobic, best for chemical resistance and filtration however not necessarily abrasion resistant and they are prone to stretching. Monofilament polyester cloths generally have the better longevity. The cloth provides for a very clear filtrate and captures all fines. The cloth is washed on the return to ensure continuous good filtration rates. The cloth can be joined by a clipper seam or can be glued on a ± 75 – 100 mm overlap using SC 2000 (rubber glue).

Vacuum Box & Wear Belts – A vacuum box is located below the belt and creates a seal with the carrier belt. The vacuum box collects the filtrate through a manifold to the receivers. The vacuum box’s topside has two wear strips made of low friction synthetic Polyamide that seal through intermediate wear belts between the bottom side of the belt and the surface of the wear strips. Since the belt is the most expensive part of the filter these endless narrow wear belts serve as a sacrificial component that absorbs the wear between the surfaces; they protect the rubber belt and secure it against vacuum leaks.

CX-PSS HBF Uniqueness

Vacuum Box Lifting Device:

On belt filters the use of counterweights is the conventional mechanism for lowering or raising of the vacuum box. The CX-PSS-developed a proprietary pneumatic system that does this automatically, saving intensive labour and maintenance costs. This system dramatically improves cleaning fines that may have settled inside the vacuum boxes and the replacement of wear strips and wear belts. This mechanism is designed to accurately seal between the underside of the main belt and the two narrow wear belts that move together along the wear strips attached to both sides of the vacuum box and apply a constant even pressure.

Another problem faced by other belt filters is that as the wear belts and slides wear, the seal between the belt and vacuum box degrades. This reduces the vacuum levels gradually and needs monthly adjustment. The pneumatic vacuum box lift creates a constant pressure on the belt and constant vacuum for the life of the wear belts and wear strips.

Cloth Tensioning and Tracking:

A pneumatic cloth tracking mechanism prevents the filter cloth from slipping sideways by moving the pivoted tracking roller forwards or backwards guiding the cloth to the left or to the right as necessary to keep the cloth centered.

Share this Page