| LINEAR

QUICK AND EFFICIENT OVERSIZE TRASH REMOVAL IN A MORE COMPACT, LOWER PROFILE UNIT, USING POSITIVE CLOTH-BENDING ONLY.

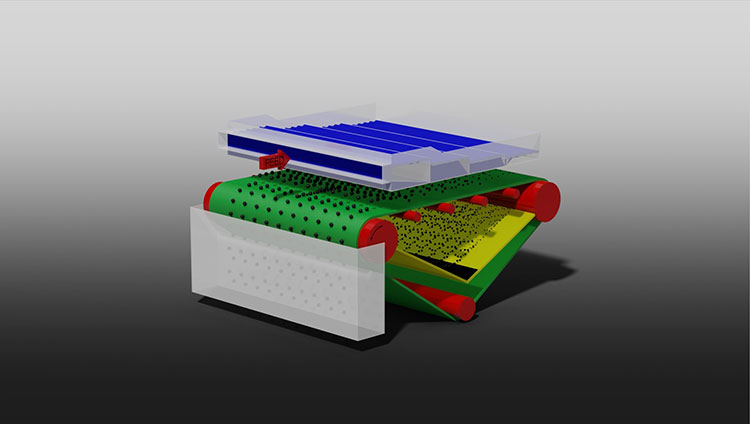

The CX-PSS Linear Screen (LS) is a screening system that removes wood fibre, trash, and oversize particles from slurried, processed ores. It is competent in removing particles between 150 and 2000 microns, and is used successfully in pre-leach and inter-stage screening, mill-circuit screening, carbon recovery/scalping, oversize recovery, and as a safety screen for thickeners and other sensitive process equipment.

CX-PSS Linear Screen Improvements

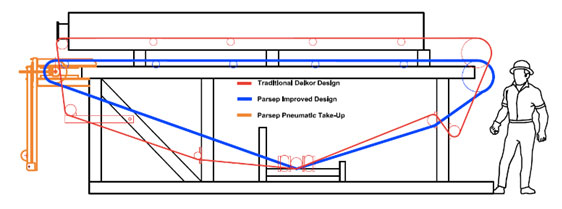

The CX-PSS LS has been re-designed to incorporate a pneumatic take-up and cloth tensioning system to eliminate cloth creasing, the most common failure of screen cloths. The newly re-designed screens are focused on simplification of operations and maintenance. By changing the cloth tracking to positive bending only, the screen profile has been reduced, producing a lighter and more compact piece of equipment. In combination with Buistex Light-Weight (LW) Rollers, manufactured from extruded aluminum, the CX-PSS LS has an increased equipment availability and overall lower operating cost per tonne of slurry.

Unique Features

| Lower profile

| Pneumatic take-up and cloth tensioning

| Positive cloth path only

| Fewer rollers and moving parts

| Use of light-weight rollers

CX-PSS Linear Screen (LS) Design

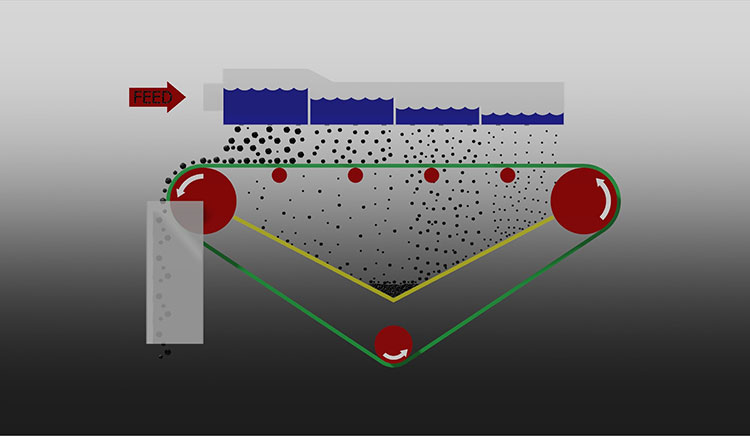

The screen uses a plastic (or steel) woven mesh that travels in a linear motion to allow the separation of particles. The mesh classifies particles depending on the aperture; particles smaller than the mesh pass through into the underflow chute, and oversize particles are captured and discharged off the end of the belt.

The CX-PSS LS can also be designed using steel belts, which are stronger, heavier, and use thinner wires and a slotted aperture to present a larger open area compared with polyester meshes of the same aperture size.

Head Pulley

The screen is driven by a rubber-lined mild steel pulley located at the oversize discharge end. The “drive pulley” is the main force behind the linear horizontal force of the belt

Drive Unit

The drive pulley is turned by a electric motor and gearbox, connected through a helical-shaft.

Screen Cloth

Screening occurs by material contacting the endless cloth which travels over the support roller. Upon discharging the material, the cloth returns to the tail pulley via a system of return rollers. The cloth is guided using a pneumatic tracking system and roller on a pivoted frame. The tail pulley achieves tensioning via a pneumatic take-up system.

Screen Wash Sprays

The mesh is returned under the screen, where it undergoes a spray to wash the mesh and discharge any material from its surface.

Share this Page